Handling tools play a critical role in modern drill pipe operations. They are used for suspending, moving, and rotating tubulars in and around the well center and on the rig floor. Although the majority of these tools are used to dynamically suspend and move tubulars in a vertical direction, some tools, such as the elevator, serve a wider array of function by moving tubulars from horizontal to vertical position.

Classification of Handling Tools :

Elevators –

A hinged mechanism that may be closed around drillpipe or other drillstring components to facilitate lowering them into the wellbore or lifting them out of the wellbore. In the closed position, the elevator arms are latched together to form a load-bearing ring around the component. A shoulder or taper on the component to be lifted is larger in size than the inside diameter of the closed elevator. In the open position, the device splits roughly into two halves and may be swung away from the drillstring component.

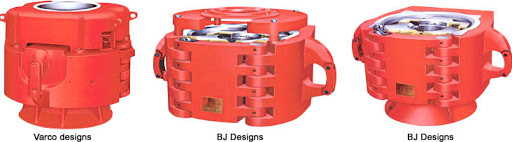

Elevators and Spiders –

Elevators and Spider are used to grip tubulars and API-sized pipes. It is designed and manufactured according to API SPEC 8A/8C for drilling and production hoisting equipment.

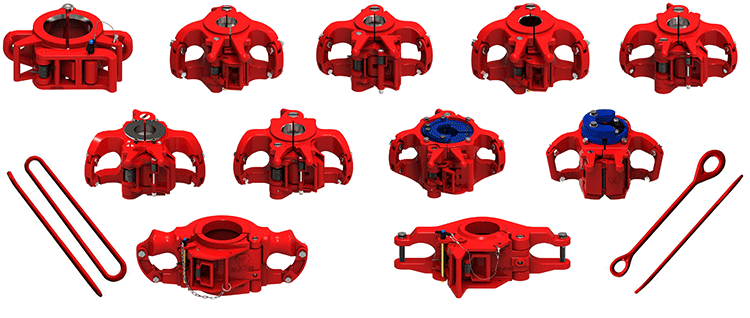

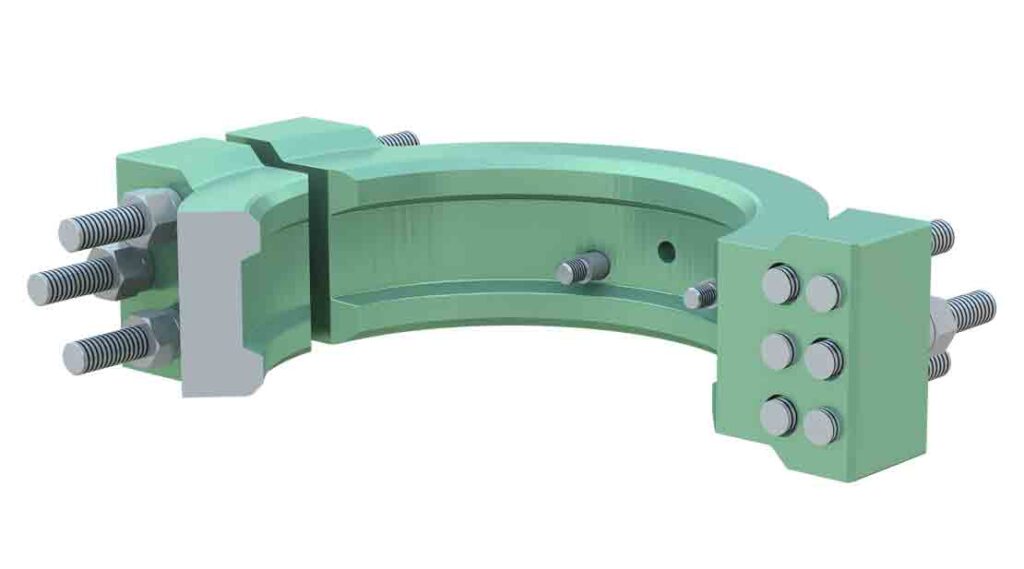

Safety clamps –

A mechanical device attached to tool strings or flush surface tubulars as they are assembled or disassembled. The safety clamp prevents the tool string from being dropped downhole accidentally if the slips or elevators securing the string lose their grip.

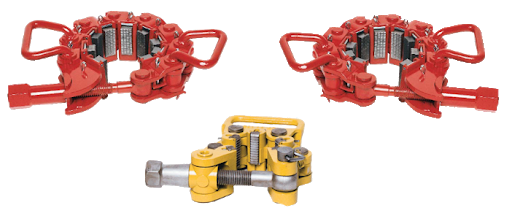

Slips –

A device used to grip the drill string in a relatively non-damaging manner and suspend it in the rotary table. This device consists of three or more steel wedges that are hinged together, forming a near circle around the drillpipe. On the drillpipe side (inside surface), the slips are fitted with replaceable, hardened tool steel teeth that embed slightly into the side of the pipe. The outsides of the slips are tapered to match the taper of the rotary table.

Manual Tongs –

Manual Tongs are tools designed for making up and breaking connections of tubular goods, from light tubing to thick walled pipe including drill collars. There are various designs and types having different torque capacity. Tongs must be used in opposing pairs, as a matter of efficiency, one set of tongs is essentially tied off with a cable or chain to the derrick, and the other is actively pulled with mechanical catheads.

Bowls and Bushings –

Master Bushings are offered ranging from 17 ½’’ to 49 ½’’ in both Pin and Square drive formats. Master Bushing & Insert Bowls are cast with high-quality alloy steel conforming to API Spec 7 K. They can also be combined-used with standard rotary slip, drill collar slip, casing slip and roller Kelly bushings.

Spinning Wrenches –

A spinning wrench is a good substitute for rotary rope or chain. It is an oil drilling tool used to offer mechanical advantage in applying torque to turn objects. Spinning wrench is designed and manufactured in accordance with API Spec 7 K. It is applicable to pipes with a wide range of diameter. There are two configurations for clamping mechanism, which are air tyre and air cylinder. Two driving and controlling styles are also available: pneumatic and hydraulic.

Best Selling Types are :- SSW10 Pneumatic, SSW30 Hydraulic, SSW40 Pneumatic Spinning Wrenches

Fast Clamps –

Fast Clamps are manual tools made to hold the riser columns on the wells during installation or maintenance of submersible pump. By using the interchangeable jaws it is possible to tighten and to hold pipes.

Stabbing Guides –

On the oilfield, stabbing guides help workers align pieces of tubing, casing, and drill pipe for female and/or male connections. These guides can be used when laying new pipelines and when connecting replacement pieces, and they are an important part of pipe protection. With these guides, users can retain control and achieve safety when connecting separate sections of pipe, and the process can be completed efficiently and correctly.

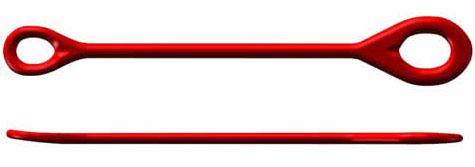

Elevator Links –

Elevator Links are designed to hang elevators from the top drive system, hooks and link adapters. Elevator Links (bails) should be inspected as it performs under high loads in harsh environments. It is manufactured in accordance to API 8C.