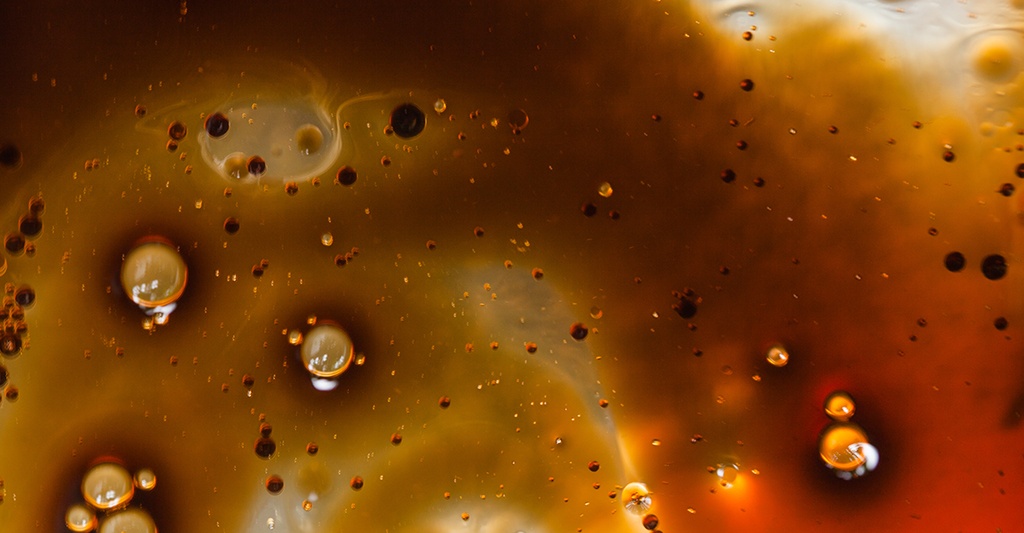

Oil Contamination causes approximately 80% of all oil system failures. This contamination takes the form of insoluble materials such as metals, dust particles, sand and rubber. The smallest particles, those below 2 µm, and better known as silt, resin or oxidation deposits are often responsible for defects. Many of these contaminants influence equipment reliability and lifetime. Nearly 100% of all problems related to contamination of oil and other fluids can be prevented with the help of CJC Oil Filter. It has an extensive experience in preventing these problems through oil maintenance, with systems developed specifically for the removal of particles, water, acidity and oil degradation etc.

OIL CONTAMINATION

Now, Questions may start arising, What does CJC Offline Filtration mean ? What is it ? What are the application? Why would anyone need it ? What are the advantages behind using it ? Why Offline Installations?

What is CJC Oil Filtration System ?

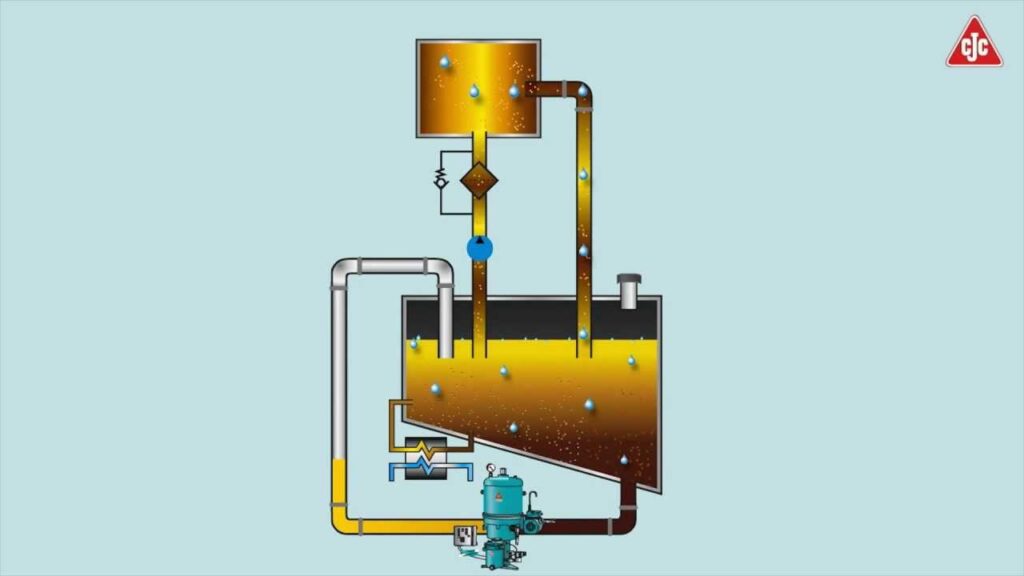

CJC is the global leader in oil maintenance with more than 60 years of experiences – designs solutions for removal of particles, water, acidity and oil degradation products (varnish) from hydraulic oils, lube oils, gear oils, diesel fuels etc. CJC Oil Filtration Systems is in most cases installed as an Offline Oil Solution removing particles down to o.8 micron.

Application?

- Marine

- Power

- Wind

- Mining

- Industries

- Offshore

Why is it required for our system ?

CJC Offline Oil Filtration System is used to overcome the problems of Oil Contamination. CJC has designed systems specifically for the removal of :

- Particles

- Free Water

- Dissolved Water

- Oil Degradation

- Oxygen / Air

- Acid

- Oil in Water

Why Offline Oil Filtration ?

Short term benefits of offline oil filtration:

- Reduced overall filtration costs (50-80%)

- No shutdown required for component changes

- Reduced equipment maintenance

- Minimal installation costs

- Minimal training required for operation

- No shutdown required for component changes

Long term benefits of offline oil filtration:

- Extended component life

- Extended oil life

- Extended in-line filter life

- Reduced downtime due to equipment failure

- Reduced environmental impact

Why Offline Installations ?

Offline installation provides a number of advantages to oil systems in industrial, marine and energy applications. It achieves the continuous-flow depth filtration that optimizes oil maintenance. In-line filters do not provide the advantages of offline depth filtration in relation to oil maintenance. Installation costs for offline filtration are less than the other systems.

Advantages ?

- Reduced machine breakdowns

- Extended machine life

- Reduced loss of production

- Extended maintenance intervals

- Reduced maintenance costs

- Extended oil life

- Reduce environmental impact

- Reduced wear and failure of components

- Increased oil & component lifetime

- Longer lifetime of in-line filters

- Increased availability

- Fewer oil changes

- Fewer unplanned breakdowns

- Reduced oil maintenance costs

- Lower environmental impact

Hence, CJC Offline Oil Filtration System is recommended to increase lifetime of equipments and systems.